“Experimental Verification of Computational and Sensitivity Analysis on Substrate Deformation and Plastic Strain Induced by Hollow Thin-walled WAAM Structure”

This paper aims to numerical and experimental analysis on substrate deformation and plastic strain induced by wire arc additive manufacturing.

The component has the form of a hollow, rectangular thin wall consisting of 25 deposition layers of SS316L on an SS304 substrate plate. Thermo-mechanical finite element analysis was applied with Goldak’s double-ellipsoidal heat-source model and a non-linear isotropic hardening rule based on von Mises’ yield criterion. The layer deposition was modelled using simplified geometry to minimize overall pre-processing work and computational time.

A new material modelling of SS316L was obtained from the chemical composition of the evolved component characterized by scanning electron microscope/energy dispersive X-ray and further generated by an advanced material-modelling software JMatPro. In defining heat-transfer coefficients, transient thermometric analysis was first performed in the bead and on the substrate, which was followed by an adjustment of the heat-transfer coefficients to reflect the actual temperature distribution. Based on the adjusted model and boundary conditions, sensitivity analysis was conducted prior to the ultimate simulation of substrate deformation and equivalent plastic strain.

Furthermore, this simulation was verified by conducting a series of automated wire + arc additive manufacturing tests using robotic gas Metal arc welding with distortion measured by coordinate-measurement machine and equivalent plastic strain measured by optical three-dimensional-metrology measurements (Gesellschaft für Optische Messtechnik).

It can be concluded that a proper numerical computation using the adjusted model and property-evolved material exhibits a similar trend with acceptable agreement compared to the experiment by yielding an error percentage up to 30% for deformation and up to 21% for equivalent plastic strain at each individual measurement point.

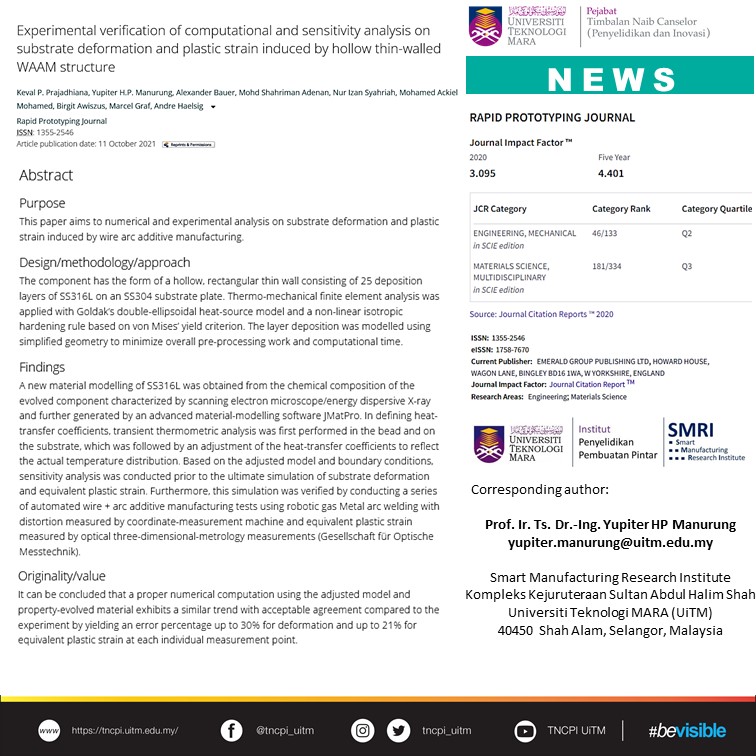

Corresponding author:

Prof. Ir. Ts. Dr-Ing. Yupiter HP Manurung

yupiter.manurung@uitm.edu.my

Smart Manufacturing Research Institute, Kompleks Kejuruteraan Sultan Abdul Halim Shah, Universiti Teknologi MARA (UiTM)